OUR CAPABILITY

Glass Edgework Options by Bear Glass

We do all types of Seamed, Polished, and Beveled edgework to make your glass & mirror safe as well as beautifull. High-quality edgeworking is essential for ensuring the durability and performance of glass components

Glass edgeworking is where the magic happens - transforming raw glass edges into sleek, precise finishes that elevate any design. Whether you're going for a modern aesthetic or a vintage vibe, edgeworking is the key to unlocking glass's full potential. With techniques like grinding, polishing, and beveling, the possibilities are endless. Get it right, and your glass project goes from functional to phenomenal. Also, high-quality edgeworking is essential for ensuring the durability and performance of glass components. Bear Glass offers a wide range of edge working options to suit various design and functional requirements. From precise seaming and grinding to polished and beveled finishes, our expertise in glass edgeworking ensures high-quality results.

Need Glass Edge-working Service?

Consult with our experts to know what is best for you.

OPTIONS

Glass Edgework Options Bear Glass Has to Offer

With latest glass edgework tools you can have a list of glass edgework options to choose from. At Bear Glass Inc, we do all types of Seamed, Polished, and Beveled edgework to make your glass & mirror safe as well as beautifull. With attention to detail and a commitment to excellence, we provide glass edges that are both durable and visually stunning.

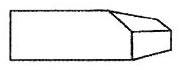

Bevel Both Sides Edge

Available in: 3/8", 1/2", 3/4"

Bevel Edge

Available in: 1/8", 3/16", 1/4", 3/8", 1/2", 3/4"

Chamfer Edge

Available in: 1/4", 3/8", 1/2", 3/4"

Clean Cut

Available in: Any Thickness

Flat Polish

Available in: 1/8", 3/16", 1/4", 3/8", 1/2", 3/4"

Miter Edge

Available in: 1/4", 3/8", 1/2", 3/4"

Pencil Polish

Available in: 3/16", 1/4", 3/8", 1/2", 3/4"

Seamed Edge

Available in: Any Thickness

PROCESS

Glass Edge Working Process

lass edge working is a critical process in glass fabrication that involves finishing and polishing the edges of glass to achieve a desired profile, smoothness, and appearance. This process is essential for various applications, including architectural glass, decorative glass, and industrial glass components. Here's a list of steps of the glass edge working process:

Step 1: Seaming

The first step in glass edge working is seaming, which involves removing sharp edges and rough spots from the glass edge. This is typically done using a seaming machine with diamond-coated grinding wheels.

Step 2: Grinding

After seaming, the glass edge is ground to achieve the desired profile and smoothness. Grinding involves using progressively finer abrasives to remove imperfections and create a smooth surface.

Step 3: Polishing

Polishing is the next step, which involves using polishing wheels and compounds to achieve a high-gloss finish. This process can be done using various polishing techniques, including mechanical polishing and chemical polishing.

Step 4: Beveling

Beveling involves cutting and polishing the glass edge at an angle to create a decorative finish. Bevels can be cut at various angles and widths to suit design requirements.

Step 5: Arrissed Edge

An arrissed edge is a type of edge finish that involves removing sharp edges and creating a slight radius on the glass edge. This is typically done using a specialized grinding wheel.

Step 6: Flat Bottom Arrissed Edge

A flat bottom arrissed edge is a type of edge finish that involves creating a flat bottom edge with a slight radius on the top and bottom edges.

Step 7: Quality Control

The final step in the glass edge working process is quality control, which involves inspecting the glass edges for imperfections, scratches, or other defects.

MACHINES

Specialized Glass Edge-Working equipments and Tools

Bear Glass's expertise in glass edge working is a game-changer for manufacturers seeking high-quality glass components. With their specialized equipment, techniques, and expertise, Bear Glass can produce precise edge finishes that meet exacting design and functional requirements. By partnering with Bear Glass, customers can unlock endless possibilities for creative expression and technical precision.

- Seaming machines

- Grinding machines

- Polishing machines

- Beveling machines

- Diamond-coated grinding wheels

- Polishing wheels and compounds

With Bear Glass's mastery of glass edge working, we can deliver exceptional results that exceed customer expectations and set a new standard for excellence in the industry.

From seaming and grinding to polishing and beveling, Bear Glass's capabilities in glass edge working are unmatched. Their team of skilled technicians and craftsmen work tirelessly to ensure that every glass component meets the highest standards of quality and precision.

Whether it's for architectural glass, decorative glass, or industrial applications, Bear Glass is the go-to partner for customers seeking exceptional glass edge working solutions.

Request a Quote

To know more about our product and to get a no obligation quote, Please fill the form below and we will get back to you soon.