OUR CAPABILITY

Glass Hole Drilling by Bear Glass

We offer the latest solutions for hole drilling using cutting-edge CNC and waterjet technology to deliver unmatched precision and efficiency.

Glass Hole Drilling

Bear Glass offers precision glass-hole-drilling services tailored for both residential and commercial needs. Using advanced drilling equipment and expert techniques, they ensure clean, accurate holes in all types of glass, including tempered, laminated, and insulated glass. Bear Glass delivers high-quality results with minimal risk of cracks or damage. Their skilled team guarantees fast turnaround and consistent reliability, making them a trusted name in custom glass solutions. Bear Glass’s glass-hole-drilling service is ideal for projects requiring exact specifications—such as shower enclosures, glass railings, tabletops, mirrors, and display cases.

Need Glass Hole-Drilling Service?

Consult with our experts to know what is best for you.

PERFECT

We Meet Your Glass Drilling Needs

Our team works closely with clients to meet custom requirements, whether for a single piece or high-volume orders. Combining craftsmanship with state-of-the-art machinery, Bear Glass ensures each drilled glass piece is flawless, durable, and ready for seamless installation.

It is a specialized process where holes are partially drilled without penetrating the entire thickness of the glass.

Stepped HolesIt involves creating holes with varying diameters at different depths, allowing for components like screws or fittings to sit flush within the glass.

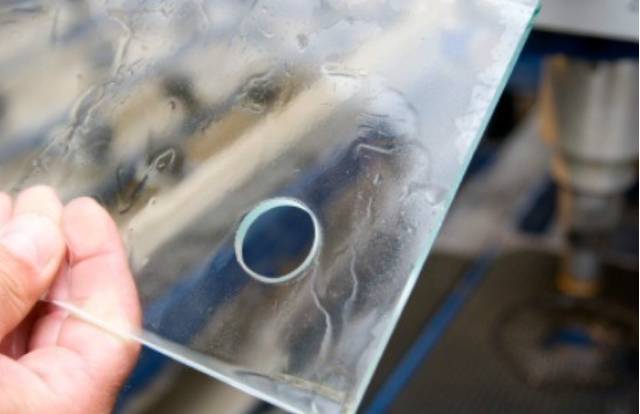

Through HolesIt involves creating clean, complete holes that pass entirely through the glass sheet. This type of drilling is ideal for installations.

It is a precise technique where a conical recess is created around a hole, allowing screws or fasteners to sit flush with or below the glass surface.

Slotting/GroovingIt involves cutting narrow channels or slots into the glass surface for functional or decorative purposes.

Shaped HolesIt involves creating custom, non-circular holes such as squares, rectangles, or irregular designs to suit specific hardware or design needs.

TECHNOLOGY

Latest Solutions Available For Hole Drilling at Bear Glass

At Bear Glass, we offer the latest solutions for hole drilling using cutting-edge CNC and waterjet technology to deliver unmatched precision and efficiency. Our advanced equipment allows us to drill a wide range of hole types.

Glass Waterjet Drilling

Precision Without Compromise. Waterjet drilling on glass is a state-of-the-art technique that uses a high-pressure stream of water mixed with abrasive particles to cut precise holes without generating heat or causing stress fractures. At Bear Glass, our waterjet drilling service allows for clean, accurate holes of virtually any shape or size—even in delicate or tempered glass—while preserving the structural integrity of the material. Unlike traditional drilling methods, waterjet cutting eliminates the risk of cracking or chipping, making it ideal for intricate and high-tolerance applications.

Our advanced waterjet technology is perfect for custom glass work where precision is critical, such as architectural panels, decorative glass, electronics, and industrial components. Whether you need round holes, slots, or complex shapes, our waterjet process delivers smooth edges and consistent results across all types of glass. At Bear Glass, we combine innovation with craftsmanship to meet the most demanding glass drilling requirements with speed, safety, and superior quality.

Glass CNC Drilling

Precision Engineered for Perfection. CNC (Computer Numerical Control) drilling on glass is a highly precise and automated process that allows for consistent, accurate hole placement across all types of glass. At Bear Glass, our CNC drilling machines are equipped with advanced software and multi-axis control, enabling us to drill complex hole patterns—including through holes, countersinks, stepped holes, and shaped cutouts—with exceptional precision. This method ensures minimal human error, consistent repeatability, and reduced risk of cracks or surface damage.

Our CNC drilling services are ideal for high-volume production as well as custom one-off projects, serving industries such as architecture, interior design, automotive, and electronics. The speed, accuracy, and flexibility of CNC technology make it possible to meet tight tolerances and demanding specifications without compromising on quality. With Bear Glass’s CNC capabilities, clients receive flawless results that are ready for seamless integration into any application.

BEST

Bear Glass, Your Partner in Glass Fabrication

At Bear Glass Inc, we collaborate with you from prototype to production, ensuring your glass fabrication project meets your exact needs. Our expertise spans multiple industries, including automotive, energy, architecture, lighting, medical, aviation, marine, and more.

Whether you're a developer, project manager, or engineer, we'll work closely with you to deliver high-quality glass solutions that exceed your expectations.

With Bear Glass Inc, you can rely on our commitment to precision, innovation, and customer satisfaction. We'll guide you through every step of the fabrication process, from design to delivery, to ensure your project is completed on time and within budget. Partner with us for exceptional glass fabrication solutions that bring your vision to life.

Glass Drilling Specifications

| Glass Types | Float Glass, Tempered Glass, Borosilicate Glass, Quartz Glass, Fused Silica Glass, Toughened Glass, etc. |

| Cut Tolerances | 0.010 |

| Maximum Thickness | 2.0" |

| Minimum Thickness | 0.125" |

| Minimum Size | 1.0" x 1.0" |

| Maximum Size | 80" x 160" |

Request a Quote

To know more about our product and to get a no obligation quote, Please fill the form below and we will get back to you soon.